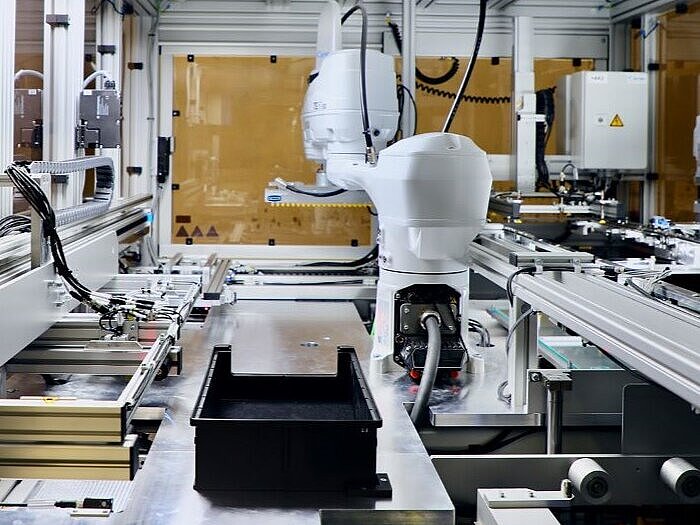

erler - automation.robotik steht für komplette und individuell passende Automatisierungsprojekte. Mit langjähriger Erfahrung und umfangreichem Know-how bieten wir für jede Anforderung flexible Lösungen, die wir mit äußerster Präzision planen und realisieren. Und das Beste: Bei erler bekommen Sie alles aus einer Hand!

0.00 Mitarbeiter

0.00 Seit

0.00 Robotersteuerungen

0.00 Projekte im Jahr

Ob es um eine Komplettlösung in Sachen Automation und Robotik geht oder um eine einzelne Leistung: Mit erler haben Sie den richtigen Partner an Ihrer Seite. Von der frühen Planungsphase über die Softwareentwicklung bis hin zur Installation und Inbetriebnahme der Hardware: Unsere engagierten Techniker und Ingenieure verstehen den gesamten Prozess.